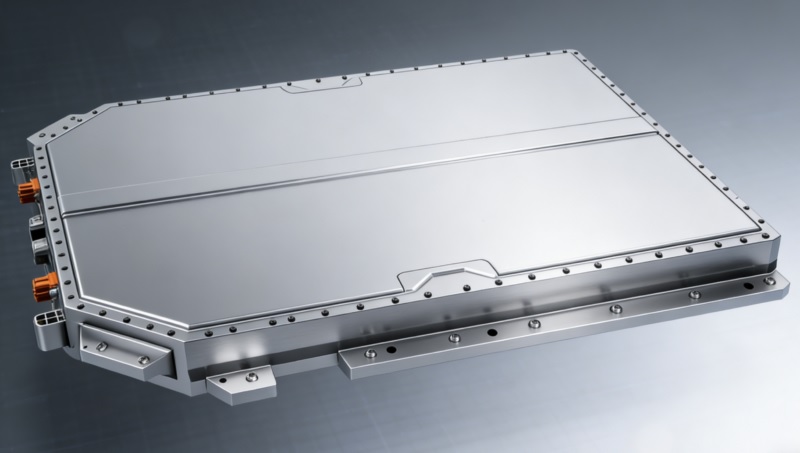

American scientists have tried to figure out why some modern EV traction batteries lose capacity earlier than forecasts predict. The focus is on lithium-ion cells with nickel-rich single-crystal cathodes: for a long time, it was believed that this structure in itself should be more durable. However, new data, mentioned by It-home, showed that the problem may be hiding somewhere other than where it had been sought before.

What they found out in the U.S.

Scientists from Argonne National Laboratory and the University of Chicago found that results obtained for polycrystalline cathodes cannot be directly applied to single-crystal materials. Yes, a single crystal is indeed free of grain boundaries, which often become “fault lines.” But that does not mean cracks will not appear at all.

Key degradation mechanism:

- within a single single-crystal particle, the reaction proceeds unevenly;

- because of this non-uniformity, internal mechanical stresses arise;

- over repeated charge–discharge cycles, the stresses accumulate;

- as a result, cracks form and usable capacity drops.

China’s answer: how “old” batteries are brought back to life

Against the backdrop of the U.S. findings, China is simultaneously developing the topic of restoring spent batteries. Laboratory approaches have been reported that make it possible to return part of the discharge capability to cells that are already considered out of service.

Molten-salt regeneration for nickel cathodes

In the second half of 2025, a team from Huazhong University of Science and Technology described a “salt” regeneration method for high-nickel lithium-ion cathodes typical of electric vehicles. According to the report, molten-salt treatment made it possible to restore up to 76% of the original discharge capacity in degraded materials: lithium ions again penetrated damaged crystalline regions and partially eliminated defects accumulated over years of cycling.

Why this is possible at all:

- many retired cathodes retain sufficient structural integrity;

- this makes high-nickel materials a convenient “target” for regeneration;

- in China, the EV market is growing rapidly, which means the flow of batteries for disposal is growing as well.

A separate track: LFP and redox approaches

In 2025, China also considered strategies for restoring lithium iron phosphate (LFP) batteries. In a review published by RSC and prepared by Jiangsu Normal University with co-authors, regeneration methods based on redox reactions were systematized, options for optimizing recycled cathode materials were described, and it was emphasized that further research is needed in a number of areas of chemistry (source: carnewschina.com).

What this means for the market and the environment

Chinese industry forecasts expect accelerated growth in the battery disposal and regeneration segment in 2024–2026: transport electrification is gaining momentum, and more and more batteries that have reached the end of their service life will be sent for recycling. This strengthens both the economic and environmental motivation to develop restoration technologies, taking into account cost factors and material composition (including issues around cobalt and possible alternative chemistries).